|

AIRLINE SUPPLIED

RESPIRATOR C.A.R.T.S.

“D” SERIES C.A.R.T. FIXED PRESSURE REGULATOR

“F” SERIES C.A.R.T. ADJUSTABLE PRESSURE REGULATOR

COMBINATION RESPIRATOR AND

PNEUMATIC TOOL SUPPLY C.A.R.T.S.

“D” SERIES COMBI-C.A.R.T.

FIXED PRESSURE REGULATOR

“F” SERIES COMBI-C.A.R.T.

ADJUSTABLE PRESSURE REGULATOR

“FDNY” SPEC C.A.R.T.

ADJUSTABLE PRESSURE

REGULATOR

PNEUMATIC

TOOL SUPPLY C.A.R.T.S.

AIR SOURCE MAX-AIR C.A.R.T.

HEAVY DUTY RED

CUSTOM C.A.R.T. COVER.

C.A.R.T. DUST COVER |

|

Super

Can Industries, Inc.

was started in September 1984 by two Pennsylvania Fire Chiefs to

construct and distribute a new product for the fire service, which they

designed and tested.

The new product was a 2.5-gallon fire extinguisher that was converted

and improved by the use of fire suppression additives and

interchangeable nozzles that drastically increased the effectiveness of

a standard water fire extinguisher. This new design permitted the unit

to be used for a multitude of task including chimney fires, Class "A''

liquid fires, as well as an increased capability in the extinguishment

of Class "A'' fire fighting. This unit was provided with a convenient

carrying bag for hands free transportation, as well as the ability to

safely climb stairs or ladders with the unit. For many years the

standard z2.5-gallon pressurized water extinguisher has been known as

the ''can'' of water. Since this new innovation drastically expanded the

capabilities of the standard "can'' it become known as the ''Super Can''

and that is where our corporate name comes from. Super Can Industries,

Inc. first CEO is one of these two chiefs and he remains the President

and CEO to this day. His 19 years as an innovative fire chief has

brought about many improvements and safety features that we always

incorporate into all of our products.

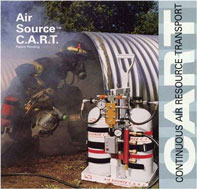

In early 1989, the president of Super Can Industries, Chief Joe Nelson,

was asked to serve as a respiratory protection advisor to the

Philadelphia Fire Department as they were in the process of

reestablishing Heavy Rescue 1, in their department. Due to the special

needs and requirements that heavy rescue operations place on respiratory

protection equipment and systems, a comprehensive study was done by

Chief Nelson on behalf of the Technical Service Division of the PFD. One

of the immediate concerns that surfaced was the lack of commercially

available long duration supply systems that met the demands of heavy

rescue. Chief Nelson embarked on a design criteria study for designing

and building the safest, easiest to use, portable, and operator friendly

continuous air resource transport (C.A.R.T.). The design and prototype

work took a total of 16 months and the members and officers of the heavy

rescue unit assisted in this process. The end result of this task was

the Air Source C.A.R.T. Super Can Industries, Inc. introduced many

''first'' in the design and construction of this type unit. They were

the first to introduce a two-piece frame assembly. The first to

introduce a fail safe, balanced piston type pressure reducer for this

type equipment, the first to have both audible and visual warnings on a

low air pressure condition, the first to introduce a flexible "main" and

"reserve" system for the air supply to the unit to prevent any

accidental out of air condition to exist. This unit became the main stay

of most metropolitan heavy duty rescue squads, based on it's safety

features, it's design features, and it's simplicity of use. Fifteen

years after the first Air Source C.A.R.T. was introduced, over 98% of

them are still in front line service today. Super Can Industries, Inc.

has always designed it's equipment to grow with the need of the fire

departments, therefore it never becomes obsolete.

|

|

The SCI Air Source® line of carts are available for

respirator supply, pneumatic tool supply, and combination respirator and

tool supply. The carts feature lightweight aluminum frames, heavy duty

cast aluminum telescoping handles, and either our electronic low

pressure warning system with LED’s or mechanical warning whistles. Some

feature detachable main frames for a lower profile, as well as an

eyebolt for hoisting or lowering.

MINI MATE

WORKMATE 200

WORKMATE 400

WORKMATE 600

AERIAL AND PLATFORM

DISTRIBUTION SYSTEM |